The RoboClaw motor controller incorporates several key technologies. These technologies guarantee reliable and safe operation in the most harsh environments. All of our products are built with wide margins guaranteeing trouble free operation. All of our motor controllers are backed with a no questions asked warranty policy.

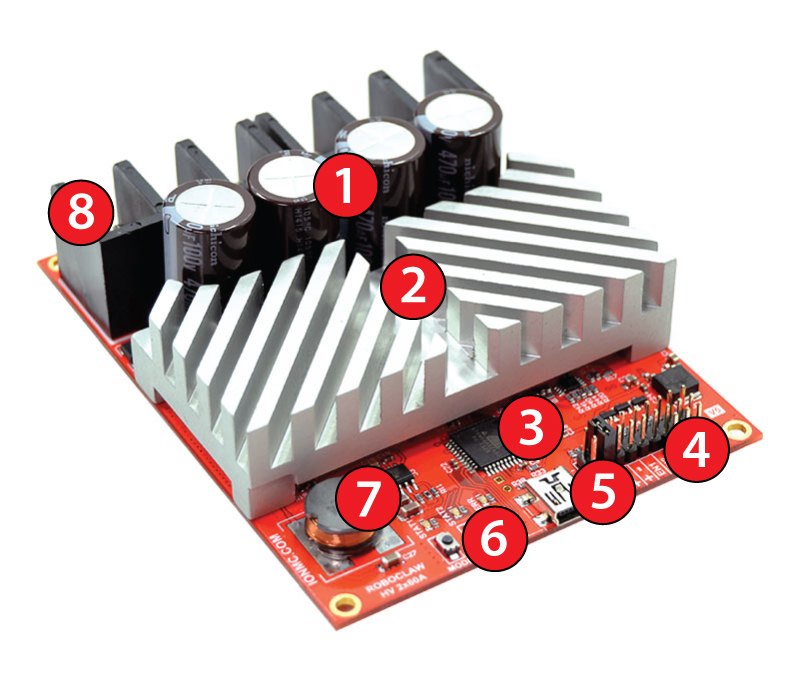

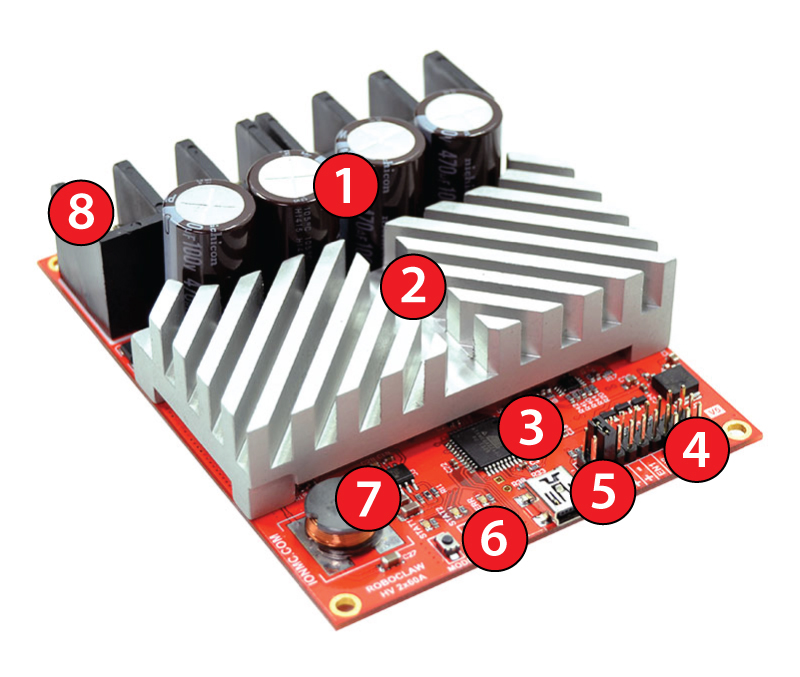

Figure 1: A RoboClaw motor controller.

1. High grade industrial temperature rated capacitors providing a minimum of two times the rated ripple current required.

2. Top side mounted MOSFET topology with aircraft grade 6061 anodized heat sink. This combination of heat sink and MOSFET topology guarantees adequate cooling in most all environments.

3. Processor hardware is used to off load functions like quadrature decoding for background processing. RoboClaw can process up to 19.6 million pulses without missing a single pulse.

4. Multi mode interface capable. Supports analog, TTL Serial, USB, R/C, PWM and more. RoboClaw can be paired to be paired with most any control system. It supports 3.3V and 5V system out of the box. No interface logic required.

5. USB interface provides a convenient way to configure RoboClaw using Motion Studio software. The USB interface can also be used to control RoboClaw for rapid integration into your next product or project.

6. External control buttons provide an easy way to configure RoboClaw in environments where a PC is not easily accessible. All modes are configurable by the on board button interface..

7. Built in switching regulator provides an efficient and reliable 5VDC power source for all of your projects. The built in BEC can be used to power interface systems such as an Arduino or R/C receiver

8. High quality shielded screw terminals protect from shorts or wires slipping off. The screw terminals work well with an assortment of wire ends including bare wire