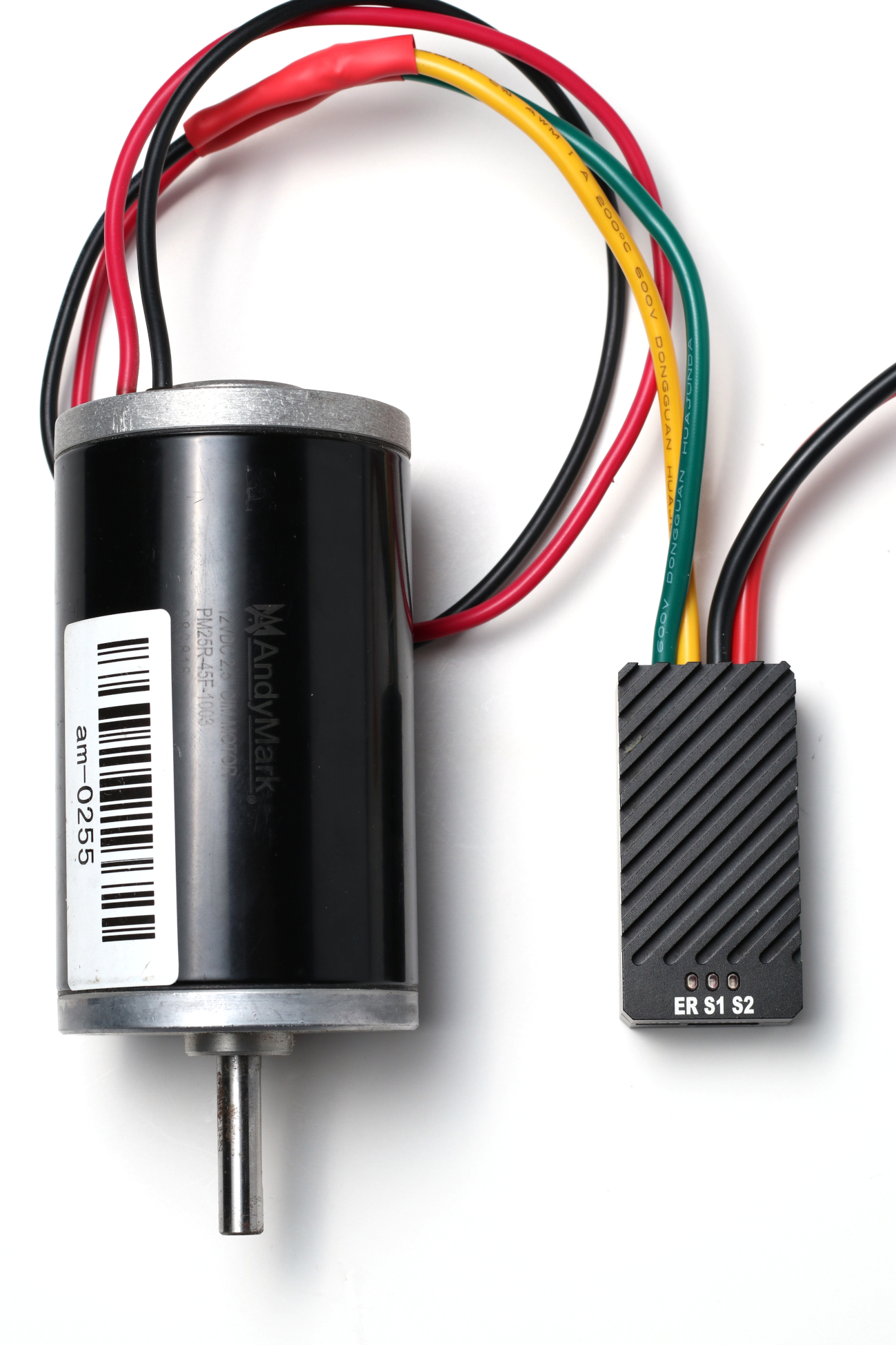

Figure 1: The Solo motor controller.

1. Wire a motor to the single channel of the Solo. The motor connections are the yellow and green wires on the Solo controller…

Figure 2: A motor wired to the Solo motor controller.

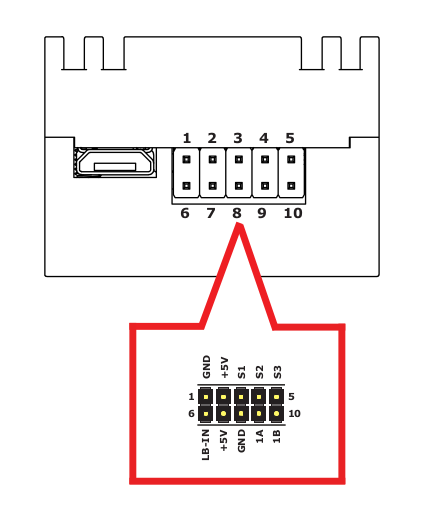

2. If an encoder is being used the encoder must be wired to the controller. The signal pins of the encoder are wired to the 1A and 1B pins of the Solo’s pin header. If the encoder requires power, wire the positive connection to the 5V pin on the header and the ground connection to the header’s ground pin. See the diagram below for the pinout of the Solo.

Figure 3: The pinout of the Solo motor controller. Signal lines are wired to the 1A and 1B pins.

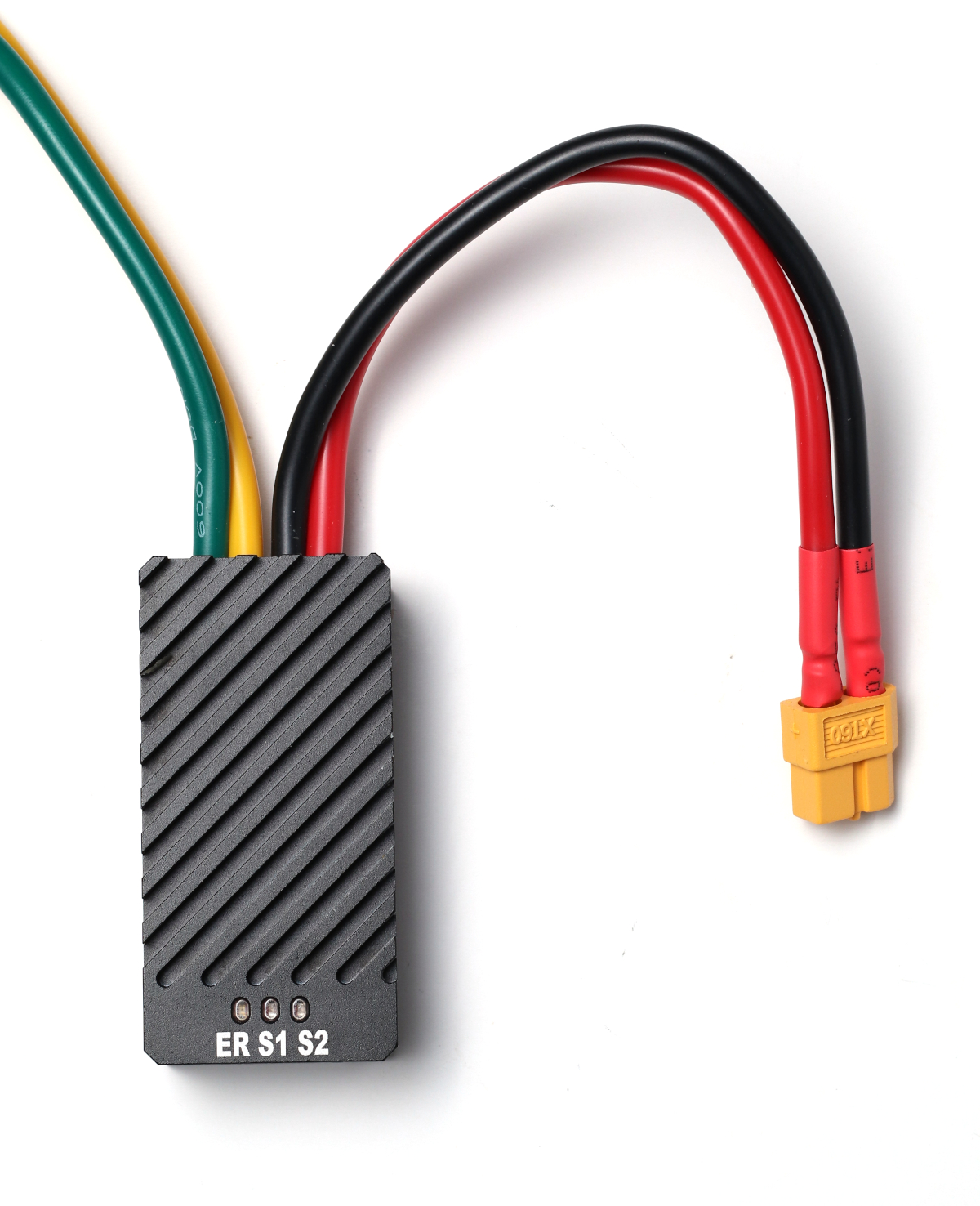

Figure 4: Power and singnal lines of an encoder wired.

4. Wire the power connections of the Solo to a battery or power supply. The red wire is the positive connection and the black wire is the negative connection. Do not wire the power source backwards or the Solo will be permanently damaged. A battery is the better power source if the Solo will be driving a large load or suddenlt starting and stopping. A battery is better able to handle the regenerative voltages created under these circumstances. The battery settings for the Solo should be set according to this app note.

Figure 5: A connector wired to the power wired of the Solo. A connector is optional but useful when using a battery.

5. Connect the Solo to a computer running Windows 7, 8 or 10 with a micro USB cable. The USB connection does not power the RoboClaw. The power supply wired in the previous step provides power to the Solo. If a power supply is being used, turn it on to power the RoboClaw.

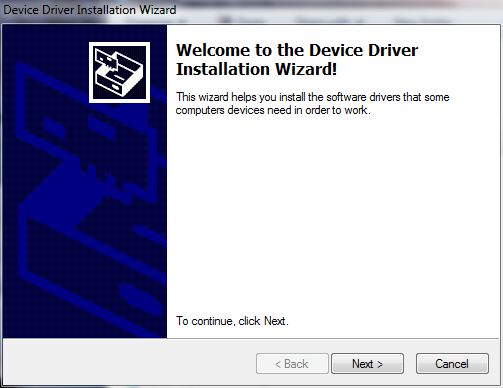

Next, Motion Studio and a USB driver must be installed. See this application note for the details of the installation.

Figure 6: The USB driver being installed.

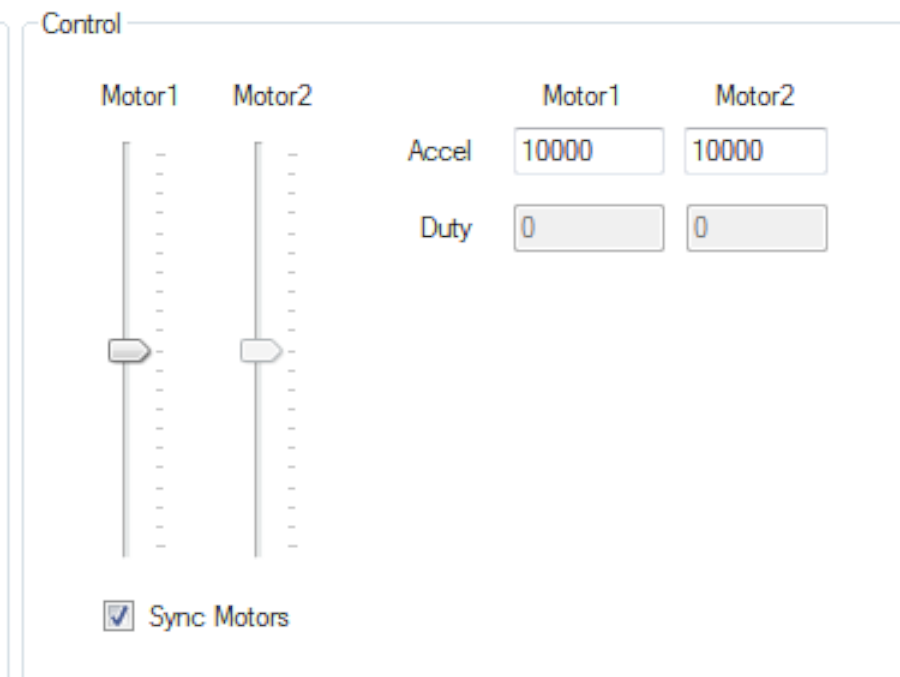

6. Open Motion Studio and connect to the RoboClaw by clicking “Connect Selected Unit” in the upper left-hand side of the application. Click on “PWM Settings” in the left-hand pane. Here the motor will be tested to make sure it’s working properly. Find the box labeled “Control”. Slide the slider for Motor 1. The motor should turn when operating the sliders. Also check to ensure that the motor turn forwards when sliding the slider up and backwards when sliding the sliders down. If the motor does not turn the proper direction reverse the wiring of the motor or reverse the motor direction in the General Settings window.

Figure 7: The motor control sliders used to test a motor.

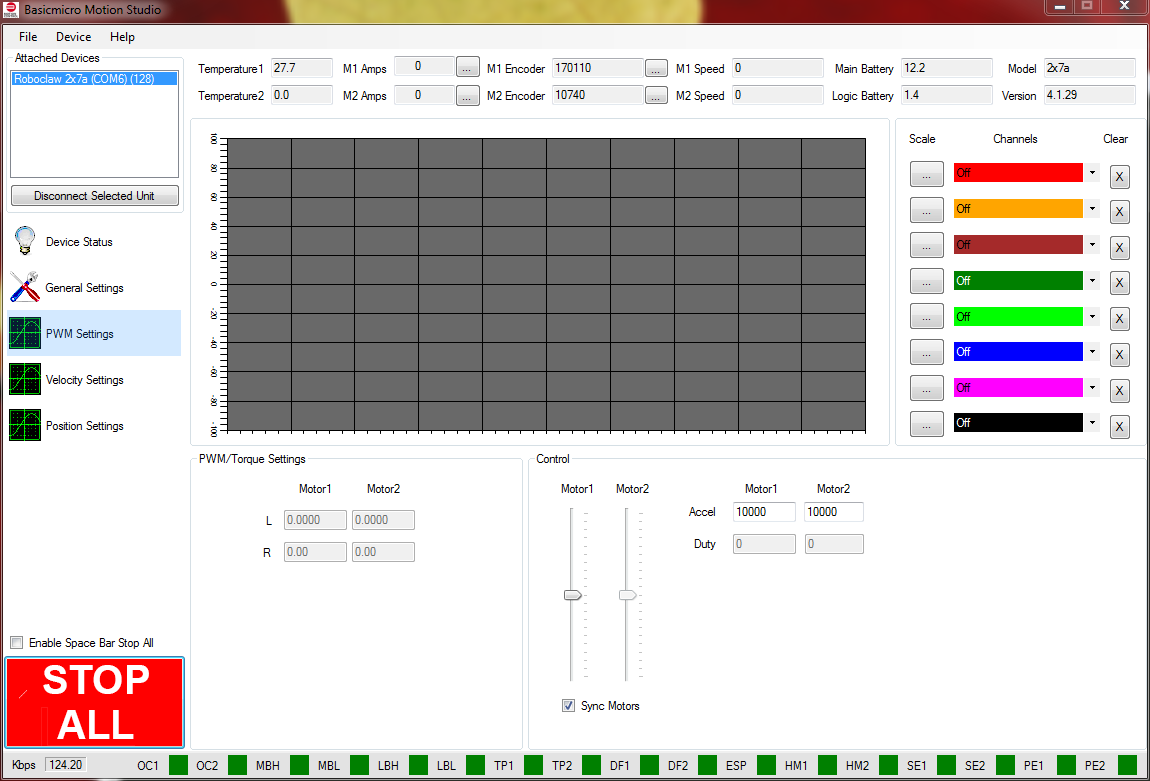

7. If an encoder is being used it should be tested while still in the PWM Settings window. Use the slider labeled “Motor 1” to move the motor forwards and backwards. Moving the slider up should move the motor forwards and down backwards. If the encoder is working properly the “M1 Encoder” value at the top of the window should increment when the motor moves in the forwards direction and decrement in the backwards direction. If the encoder counts do not increment and decrement properly reverse the encoder signal connections.

Figure 8: The encoder count is at the top of the PWM Settings window.

8. If an encoder is being used the motor and encoder combination must be tuned for position control. See this application note for instruction on auto-tuning for position control. Be sure to use the PIV tuning method when autotuning for position control.

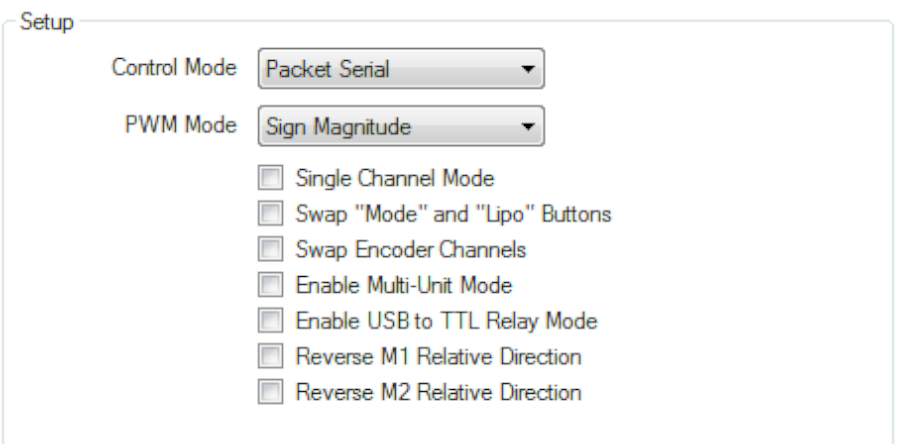

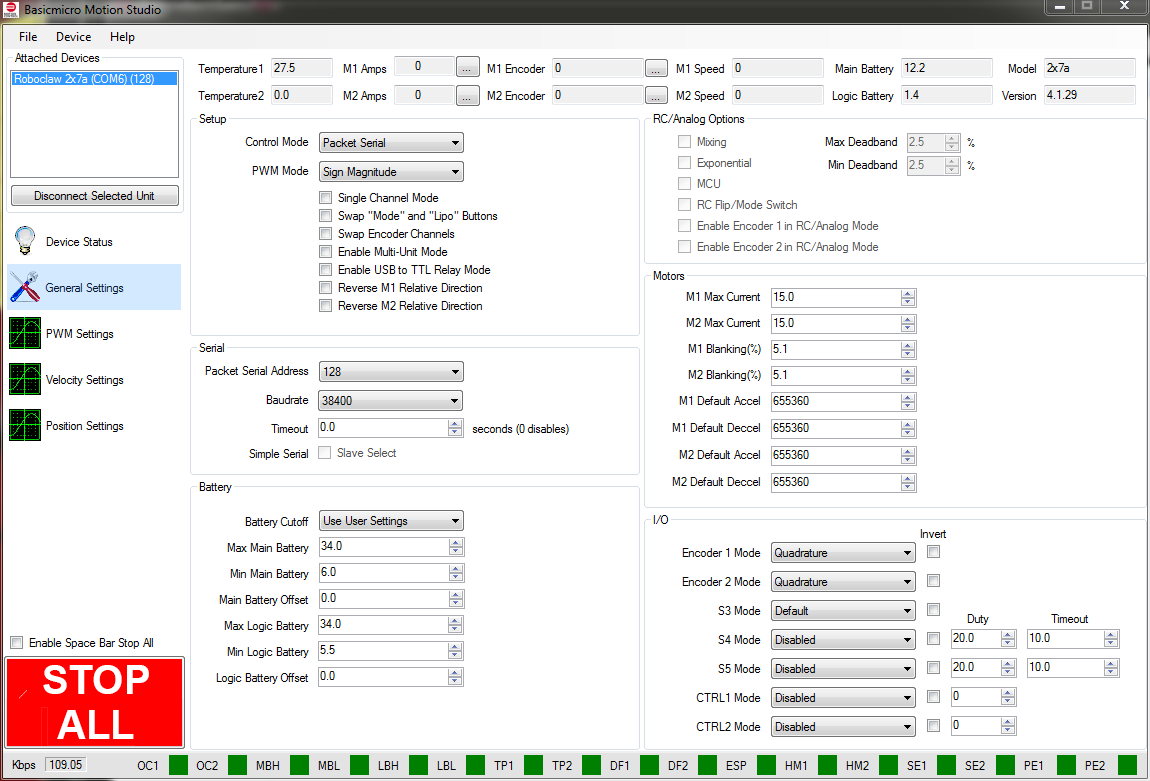

9. The control mode must be set correctly for the mode of operation desired. The options are: packet serial, simple serial, rc and analog. Click on General Setting on the left-hand side of the application. Packet serial is used with the available libraries to allow a microcontroller to operate the controller. Simple serial is a simplified version of packet serial for use with microcontroller. RC mode allows an RC radio and reciever to operate the controller. Finally, analog mode allows analog devices such as joysticks and potentiometers to control one or both motor channels.

While still in Motion Studio click on General Settings on the left-hand side of the application. Locate the pane labeled Setup and set the dropdown labelled Control Mode to the desired mode.

Figure 9: Setting the control mode.

10. Save the settings to the board by clicking “Device” in the menu at the top of the application and then clicking “Write Settings”.

Figure 10: The device settings are saved at the top of the General Setting window.

10. More information on using each mode can be found in our application notes. Some additional wiring and software configuration must be done for some modes. Below are links to the relevant articles.

Using a microcontroller in packet serial mode

Using Arduino with RoboClaw

Using the Arduino Library

RC ModeBasic RC Mode Setup

Analog ModeAnalog Control